Welcome to Union Tubers – Retubing Experts

At Union Tubers, we take pride in being leading experts in chiller, boiler, and absorber retubing. Our team possesses unparalleled expertise in supporting Eddy current testing contractors, HVAC contractors, and direct to customers. We are pleased to serve the United States and Northern Mexico areas.

When you choose Union Tubers, you can be confident that your chiller, boiler, or absorber will receive the highest level of expertise and precision. We are committed to delivering exceptional workmanship and ensuring the long-lasting performance of your equipment.

Our services include:

- Turnkey Retubing

- Epoxy Coating

Turnkey Retubing

As an option, we make it simple for our Eddy current testing and HVAC contractor customers by providing turnkey solutions. We can handle the entire retubing project for you including:

- LoTo

- Recovering the refrigerant or LiBr charge

- Isolating water flows

- Removing heads

- Leak checking

- Charging

- Returning chiller to service

The image below shows an absorption chiller that’s kept in a nitrogen purge during retubing:

Other Specialty Services

Internal Tube Support Replacement

We understand the critical role that tube supports play in the overall performance and longevity of your equipment. With meticulous precision, our highly skilled technicians ensure that each tube is expanded at the proper distance and to exact specifications. By doing so, we minimize leak risks that can be caused by vibration or misalignment.

Tube Sheet Replacement

The process of replacing an eroded tube sheet is an invasive process that includes cutting out the damaged tube sheet and expertise in welding on a new custom tube sheet. This requires aligning the new sheet with the tubes and process requires prepping the tubes, applying sealant, and carefully expanding the tubes for the right amount of elastic deformation.

Epoxy Coating

Epoxy coating offers several benefits for condenser tube sheets and heads. It provides excellent corrosion resistance, protecting against damage from corrosive substances and extending the lifespan of the condenser. It also helps prevent leaks and ensures the integrity of the tube sheet and head, minimizing downtime and potential damage. Epoxy coating can withstand high temperatures, making it suitable for demanding condenser applications.

Video of tube trimming prior to epoxy coating:

Gif of hydraulic tube removal tool in action

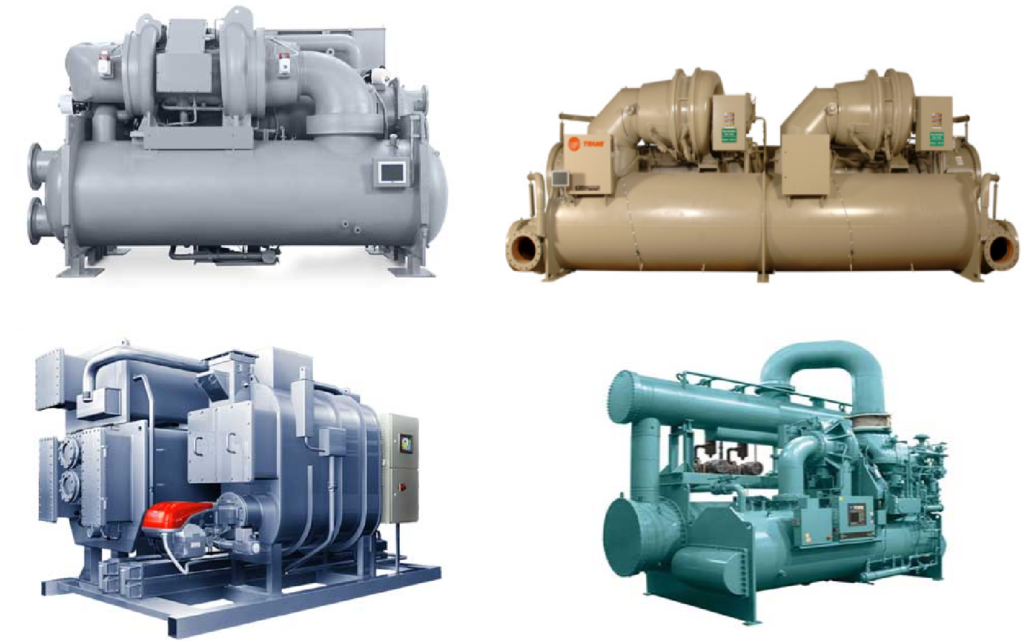

We service dozens of chiller and boiler makes, models, and vintages including: Carrier, Trane, York, Daikin, MultiStack, Smardt, McQuay, Westinghouse, and others.

HAVE ANY QUESTIONS?